When chainsaws are maintained and used correctly, they are powerful, useful tools helping with tree care and removal, clearing thick brush, and cutting fallen branches into movable pieces.

Conversely, chainsaws could be one of the most dangerous pieces of small equipment your team uses when handled and maintained incorrectly.

Here are some things to keep in mind before, during, and after using a chainsaw.

Wear All Safety Equipment

Safety can’t be stressed enough! Chainsaws can do some serious damage. If you’re not paying close attention to what you’re doing, you better hope you’re wearing all the proper safety equipment if the chainsaw kicks back or the branch you’re cutting decides to surprise you.

Be sure the chainsaw operators use all available personal protective equipment (PPE). PPE includes:

- Helmets (with visor and hearing protection)

- Safety Goggles

- Protective Jacket

- Chainsaw Gloves

- Chainsaw Chaps or Pants

- Steel-Toe/Kevlar Boots

Schedule inspections of safety equipment based on how often it’s used. Damaged or worn PPE needs replacement immediately.

Do a Daily Inspection/Cleaning

Be sure the chainsaws are ready for whatever lies ahead. Daily chainsaw inspections ensure your team's safety and better efficiency and longevity of the equipment.

Here’s a quick chainsaw inspection checklist to get you started:

- Remove the clutch cover, bar, and chain--clean any accumulated debris.

- Make sure the lubrication hole is not blocked.

- Clean the bar groove and inspect for wear. Make certain the bar is straight.

- Inspect chain drive sprocket, air filter, and fuel lines for any issues or damage.

- Reassemble the chainsaw.

- Tighten or loosen the chain if necessary. The chain is correctly adjusted if you could lift it about ⅜ an inch at the top center of the bar.

- Check fasteners, screws, and bolts to make sure they are tight.

- Check the machine for any visible cracks or signs of wear.

- Wipe down the outside of the machine.

- Check chain catcher. Replace it if damaged.

Only Use Sharp Blades

Like your mowers, clean, sharp edges make a huge difference in how a chainsaw operates. When the blades are dull, it causes the chainsaw to work harder. Frequently using dull blades will affect the lifespan of the chainsaw.

A worn chain also can compromise the safety of the operator. Anyone who accidentally ran a chainsaw into the ground knows the difference between a sharp chain and a dull one. If you or someone on your team starts noticing your putting force into the cut, it’s time to sharpen--or change--blades.

That extra push put into a cut may cause a loss of balance when the cut is complete. Nobody wants to be holding a running chainsaw when trying to regain balance.

If your chainsaw goes dull in the field, it’s probably best to swap it out with a different chain. It is possible to sharpen your chain in the field--if necessary--but it can be time-consuming and, without something to hold the chainsaw in place while you’re sharpening, may not be as effective as someone doing it in the shop.

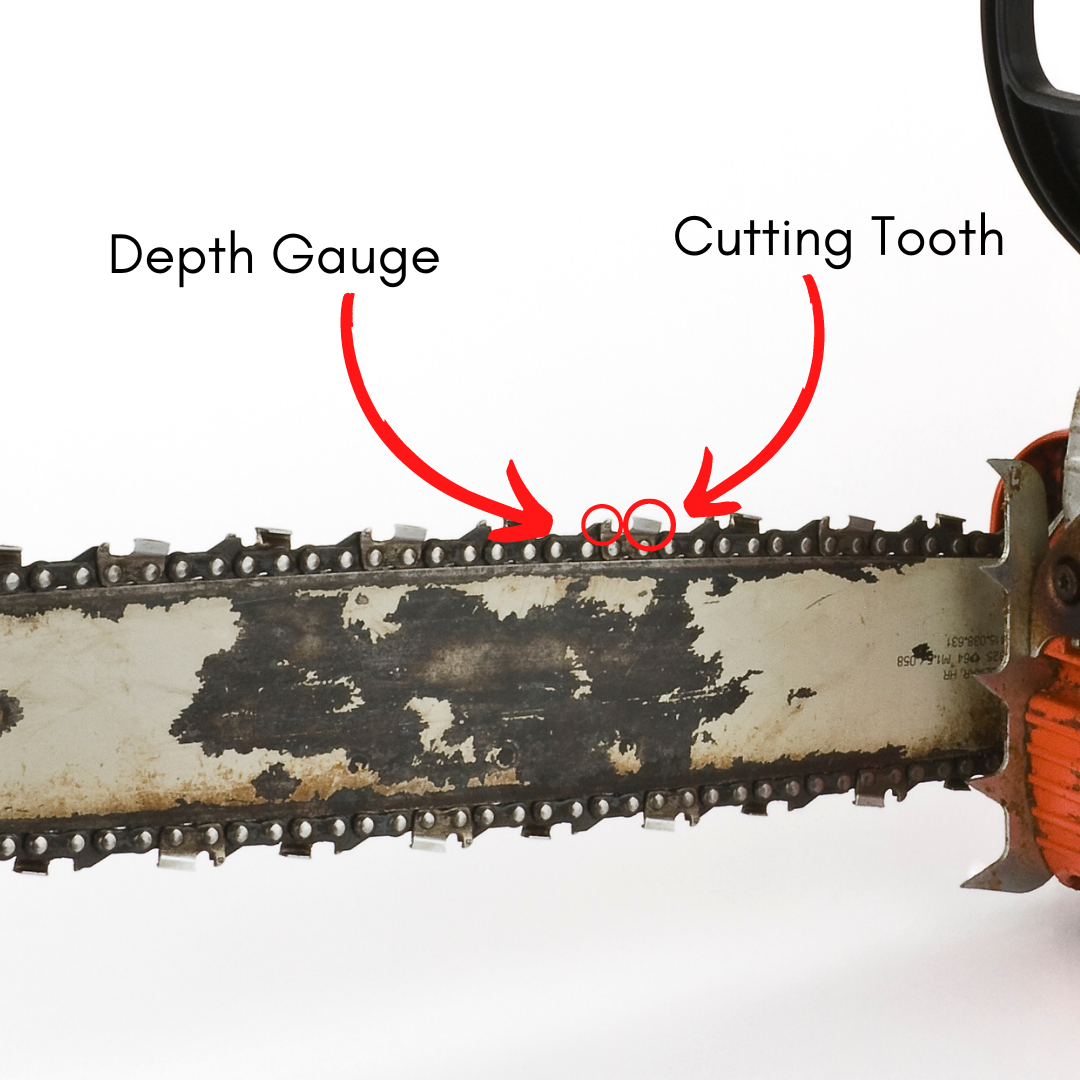

When sharpening, you want to check the cutting teeth and depth gauges.

Sharpening the Cutting Teeth:

The cutting teeth are the small blades on the chain shaped like sharp teeth (see image above).

Here’s how to sharpen cutting teeth:

- Secure the chain to prevent movement.

- Put the chain brake on.

- Position file depth gauge on the chain. The gauge’s arrows will point toward the front of the chainsaw.

- File every other cutting tooth using a smooth and even pushing stroke at a right angle. Give it a little bit of upward pressure and only file in one direction.

- Turn the saw around and file the other cutting teeth in the same way.

Filing the Depth Gauges:

The depth gauges on a chain are small tips by each cutting tooth. They control how deep the cut goes and how fast material gets removed from the cut. As a rule of thumb, depth gauges should get filed every 3rd time you sharpen a chain.

Here’s how to adjust the chainsaw’s depth gauges:

- Clean the chain of any grease or debris.

- Secure the chain to prevent movement.

- Set the guide tool on the chain to cover a cutting tooth.

- File down the depth gauge until it is even with the guide tool.

- Continue the process until all depth gauges are even with the guide tool.

Don’t Let Your Chainsaw Run Dry

If you’re paying close attention to the chainsaw, it hints when the fuel tank is just about empty. That certain sputter or the rev of the engine. Consider those sounds the cue to stop the chainsaw and refuel.

Working the saw until it is entirely out of fuel is hard on the tool. The fast-moving parts don’t have the oil to lubricate and cool them, causing premature wear and decreasing the saw’s lifespan.

Chainsaw Safer With Paper(Work)

Keep records of inspections and maintenance to ensure all chainsaws receive proper care. Dedicate a spot in the file cabinet for the records--or store them digitally.

Having records helps you determine if supplies, extra service, or a replacement chainsaw is needed. Also, records indicate that the chainsaws received regular maintenance in case of an accident.

Finally, schedule periodic chainsaw inspections to ensure everything is in good shape. The frequency of inspections depends on how often the chainsaws get used. You may want to schedule monthly or even weekly during the cutting season.